From Waste to Sovereignty: How TITAN and ASMARA Build Europe’s New Biomanufacturing Landscape

TITAN and ASMARA are not just platforms for converting waste into energy. They are flexible, modular bio-manufacturing hubs designed to anchor a new industrial landscape—one built on sovereignty, sustainability, and regional regeneration.

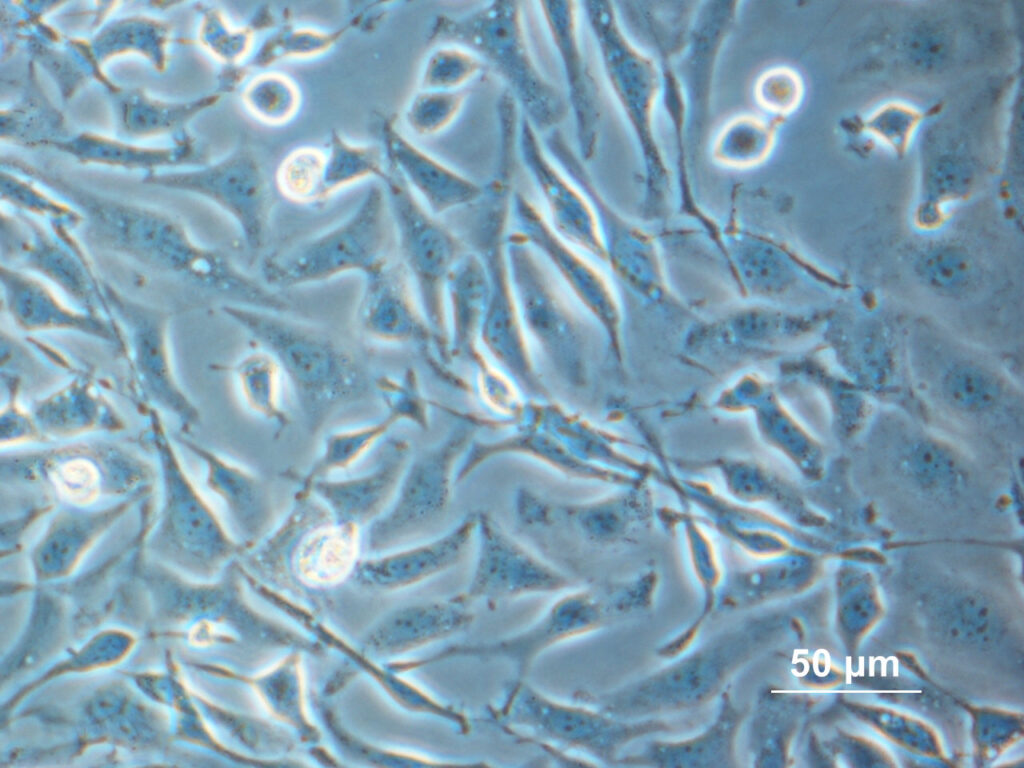

At their core is a powerful integration of Hydrogen Producer Gas (HPG) and Targeted Microbial Fermentation (TMF)—a pairing that unlocks the ability to produce a vast spectrum of high-value outputs: fuels, bioplastics, chemicals, proteins, and even advanced medical bioproducts like CHO (Chinese Hamster Ovary) cells.

But more importantly, these platforms offer a way to reindustrialise rural Europe, create high-quality employment in overlooked regions, and reduce the continent’s dependence on imported fuels, chemicals, and biopharmaceutical precursors.