Harnessing PEGASUS: Direct Air Capture Meets HPG + TMF in the Race to Regenerate Carbon

How TITAN and ASMARA transform carbon from problem to product in line with EU priorities

As Europe confronts rising temperatures, tightening emissions targets, and increasing resource instability, a fundamental shift is underway: carbon is no longer seen only as waste, but as feedstock. This shift is visible in new industrial strategies, circular economy goals, and bioeconomy frameworks—but it needs infrastructure to deliver.

That’s where PEGASUS, a modular Direct Air Capture (DAC) system developed for integration with the TITAN and ASMARA platforms, enters the picture. It offers a breakthrough solution: capturing carbon from the air or industrial sources and transforming it into fuels, chemicals, materials, or even nutrients, via the microbial fermentation infrastructure already embedded within TITAN and ASMARA.

This is not speculative. It is already working in pilot, and it fits squarely within existing and forthcoming EU directives.

TITAN and ASMARA: Carbon-Circular by Design

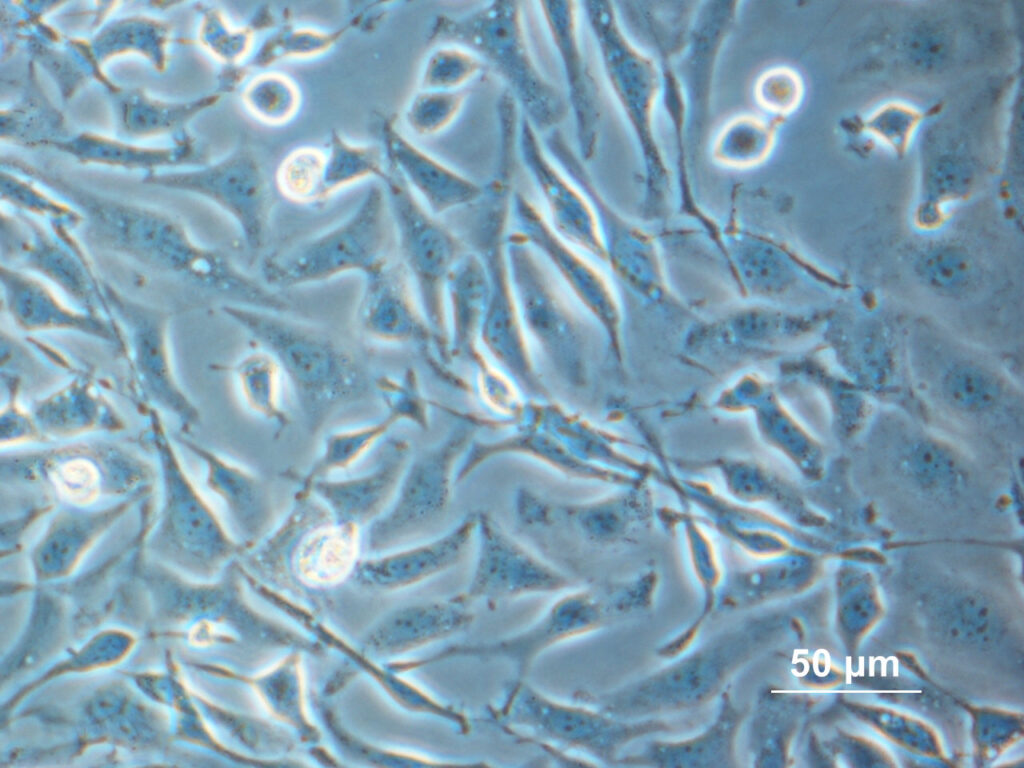

TITAN, built for rural zones, converts forest and agricultural waste into hydrogen-rich gas (HPG) and uses microbial fermentation (TMF) to convert that gas into second-generation ethanol, biochemicals, and energy. ASMARA performs the same function in urban areas using sorted municipal solid waste (MSW). These platforms are modular, scalable, and already aligned with Europe’s Green Deal, REPowerEU, and Fit for 55 objectives.

Adding PEGASUS enhances these platforms by introducing a steady, high-purity stream of captured CO₂, which TMF microbes can metabolise directly. Rather than storing the carbon underground, as most current DAC-to-CCS models propose, PEGASUS routes the carbon into productive pathways—ensuring economic as well as ecological value.

This becomes especially powerful when blending CO₂ from multiple sources. For example:

- Captured emissions from cement or steel plants (typically high in volume but lower in purity),

- Ambient CO₂ captured via PEGASUS DAC (typically lower in volume but high in purity).

Blending both streams produces an optimised fermentation feedstock suitable for high-volume biofuels or specialised bio-based outputs. In fact, the purity of DAC opens entirely new metabolic pathways, allowing the production of advanced molecules such as bio-based solvents, high-purity organic acids, or even smart proteins like insulin analogues and bioactive lipids.

This is not just a carbon-negative process. It is biomanufacturing from thin air.