The Machines That Heal—and the Circular Economy They’re Building

She looks almost human. Porcelain skin, careful eyes, anatomical symmetry—delicate, not threatening. A beautiful contradiction. The image evokes a future we’ve long imagined: robots that walk beside us, feel with us, care for us.

But this isn’t the warm robot we meant.

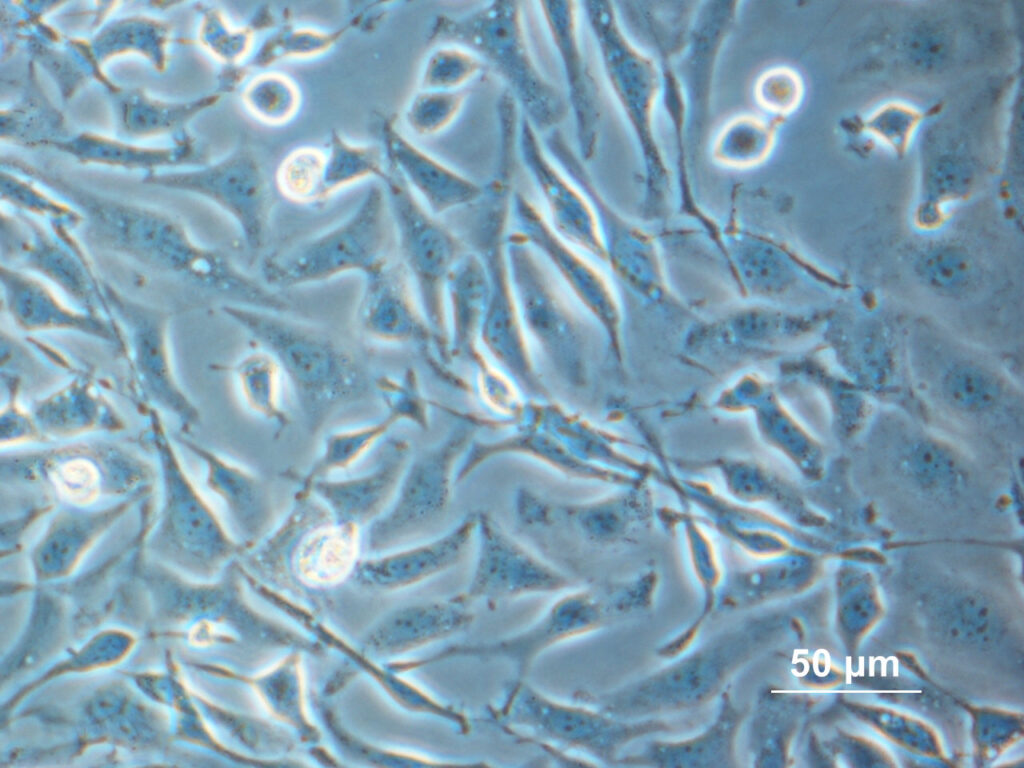

Because the real warm robots—ours—don’t smile or stand. They don’t blink, speak, or age.

They are microbes.

Alive, invisible, programmable.

They live in tanks. They breathe carbon. They manufacture the building blocks of the post-pollution world: fuels, chemicals, nutrients, and materials. And now, aided by generative AI, they are evolving—stacking complexity, mimicking natural processes, and operating with the efficiency of the human brain and the regenerative elegance of skin and bone.

We call this new capability Industrial Lifestacking.

It’s not robotics. It’s regeneration.

Not imitation—but biological infrastructure, scaled.

The Living Stack

Long before artificial intelligence could speak, microbes were building. While generative models were still learning language, fermentation vessels were already producing ethanol, biodegradable polymers, and essential proteins from nothing more than carbon waste and biological design.

What makes this possible is a structure we call the Living Stack—a three-layered system that turns industrial chaos into organic precision:

AI serves as the design layer, where biological systems are mapped, metabolic pathways are simulated, and yield efficiency is optimised.

Gene Editing functions as the software layer, rewriting microbial DNA to perform intentional functions—from synthesising alcohols to building amino acid chains.

Targeted Microbial Fermentation (TMF) forms the hardware layer, where gas-fed microbes in controlled environments transform design and code into physical product.

This stack doesn’t run on electricity alone. It runs on carbon. It doesn’t output noise or abstraction. It outputs life.