Warsaw 12 October 2023

In the heart of Poland, the Syngas Project, a subsidiary of London-based SOLIDEA Group Ltd, stands as a pioneering force in sustainable energy with its groundbreaking TITAN project. This short article delves into the evolution and impact of the Syngas Project, highlighting the transformative journey from the PowerCan project to the development of TITAN.

The PowerCan Project and TITAN’s Genesis:

The roots of the Syngas Project trace back to the PowerCan project at RUMIA shipyards in Gdynia in 2017, Poland. From these beginnings, the team embarked on the ambitious mission to create TITAN, initially conceived as a “Cookie Cutter” 20MW midsized, distributed, utility-scale modular Combined Heat and Power (CHP) plant with two production islands. Notably, in 2019, Island Two underwent a remarkable transformation into a Microbial Fermentation Unit, showcasing the project’s adaptability and commitment to cutting-edge technologies.

In April 2023, the European Union approved the ReFuelEU Aviation proposal which imposes blending mandates on synthetic fuels for aviation, increasing from 0.7% in 2030 to 28% in 2050.

Renewable Electricity and Biofuel Production:

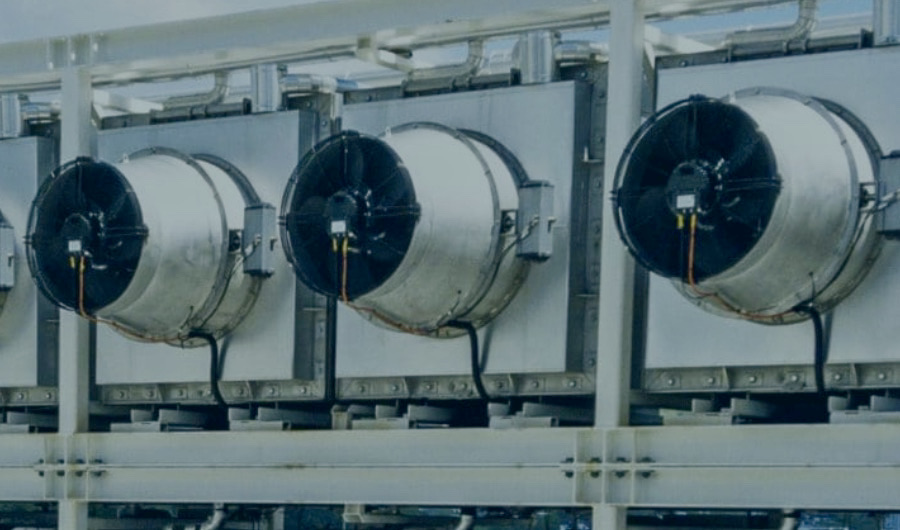

Island One of TITAN continues to serve as a CHP plant, providing renewable electricity on demand. This sustainable power is not only utilised to fuel TITAN’s operations but also exported, contributing to the broader energy landscape. TITAN’s capability to produce spare renewable electricity on Island One mitigates feedstock risk through “reach and cache” policies implemented to capitalise on severe weather and seemingly more common 100-year adverse climate events which could risk the short-term availability of feedstock in future.

Simultaneously, Island Two boasts the daily production of 60,000 litres of 2G EtOH (Ethanol) through microbial fermentation and adding a significant renewable fuel source to the market. Syngas Project’s strategy is to build 12 TITAN in Poland, enough 2G EtOH (Ethanol) to supply Syngas Project’s own SAF Refinery. A local SAF refinery in Poland would establish Polish Airports as the most desirable hubs in Europe for local and intercontinental carriers feeding passengers in and out of Europe and from Europe’s dead centre, SAF being the main catalyst for success.