Warsaw Monday June 2, 2025

Poland’s district heating (DHN) infrastructure is both a legacy achievement and a growing liability. Half the country depends on centralised heat, yet the economic foundation of that system is in crisis. The cost to sustainably generate clean heat in Europe is around EUR 0.50 per kilowatt-hour. In Poland, the market pays only about EUR 0.25/kWh. This is not a viable business model. It is a slow failure in plain sight – a structural mismatch between what heat costs to produce and what consumers can afford to pay.

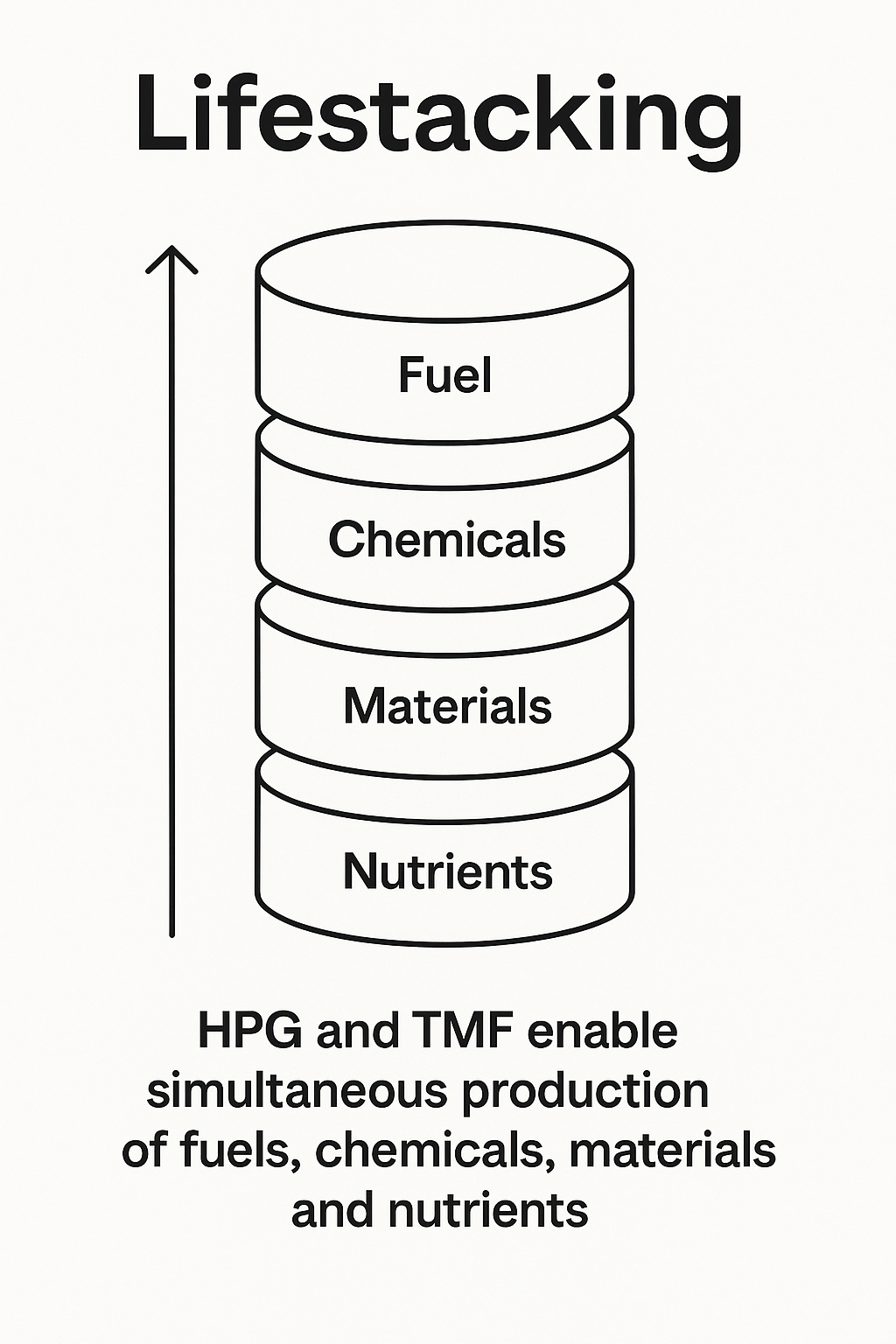

But what if there were a way to produce heat sustainably, affordably – and without relying on it as your main income stream? That’s the proposition of TITAN and ASMARA. These are not conventional power plants. They are modular, carbon-negative industrial platforms that happen to produce a lot of clean, surplus heat – and that changes everything.

Heat as a By-Product, Not a Revenue Anchor

TITAN’s Island One is a biomass-fuelled Combined Heat and Power (CHP) plant, running on forest residues converted into hydrogen producer gas. It produces stable, 24/7 electricity – and in doing so, generates significant volumes of usable heat. But this heat is not the commercial driver of the system. It is a process by-product.

Because TITAN’s business model does not depend on selling heat for profit, it can afford to export heat into Poland’s existing DHN pricing environment without financial strain. In fact, it thrives there – simply because heat is not our bottom line. That distinction makes TITAN a structural fit for the Polish context, where heat prices are capped and economic pressure is high.